Years of

Experience

We are a dedicated team of over 60 R&D specialists and 400+ employees by full in-house manufacturing capabilities, passionate about transforming visionary ideas into exceptional timepieces. With two decades of combined experience, we partner with brands, entrepreneurs, and creators to navigate every step of the custom watch development journey—from initial concept to final production. Our mission is to blend innovative design with precision engineering, ensuring each watch we craft not only tells time but also tells a unique story.

CNC Machines

R&D team

Cooperative brands

Patents

Partner with us for a future built on integrity and shared success.

Create fully personalized watches from design to production, realizing your unique brand watch with our end-to-end ODM service.

Read More

You provide the blueprint. We deliver high-quality products, manufactured to your specifications with guaranteed quality.

Read More

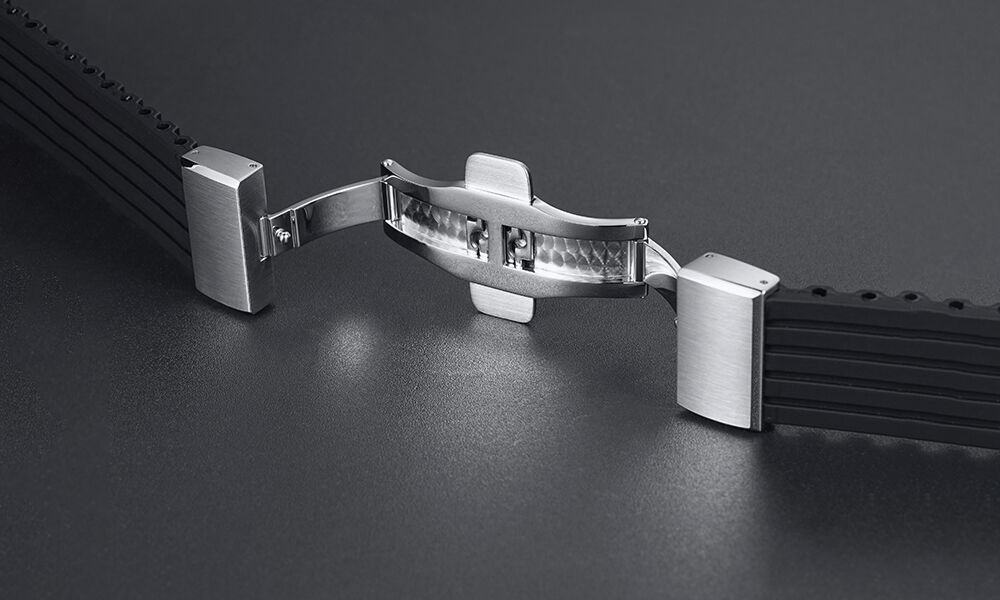

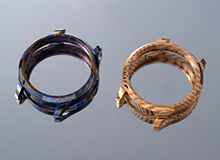

Develop exclusive watch accessories (dials, bracelets, cases, buckles, crowns, etc.) with full-process customization, supporting both ODM and OEM collaborations.

Read More

Personalize our standard accessories (e.g., universal buckles) with branded logos or materials via efficient OEM solutions for rapid branding.

Read More

・Client Provides: Brand philosophy, inspiration images, preliminary graphic design drafts, reference timepieces, functional requirements, target consumer group, price positioning, dimensional standards, etc.

・Project Discussion Meeting: Review and structure the client's project, revise project details, obtain client confirmation on the project, and reach a mutual agreement.

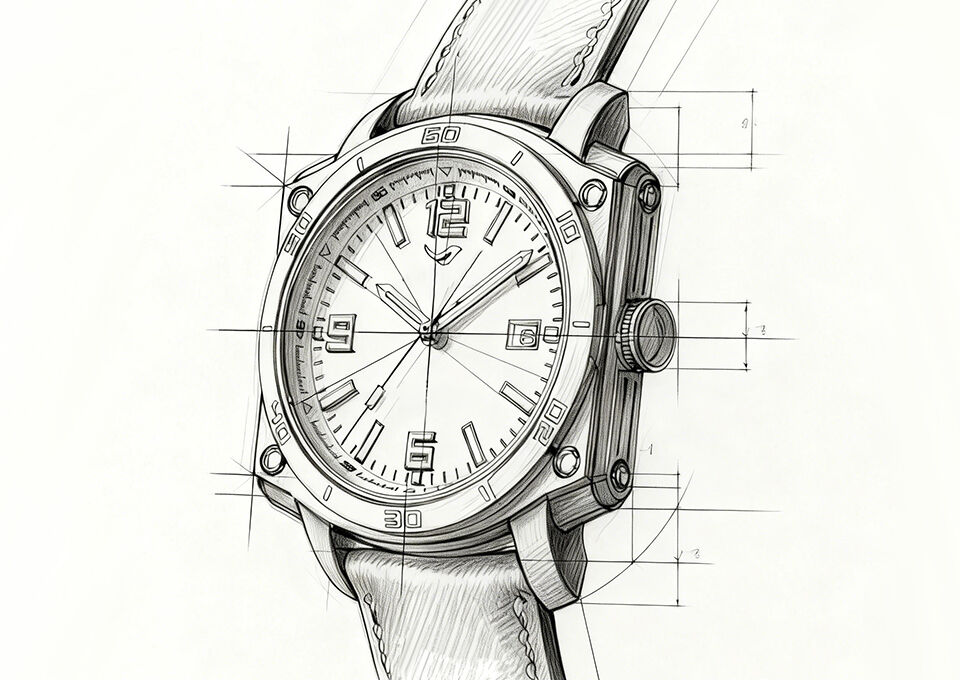

Designers provide two 2D renderings to showcase the concept's visual effect.

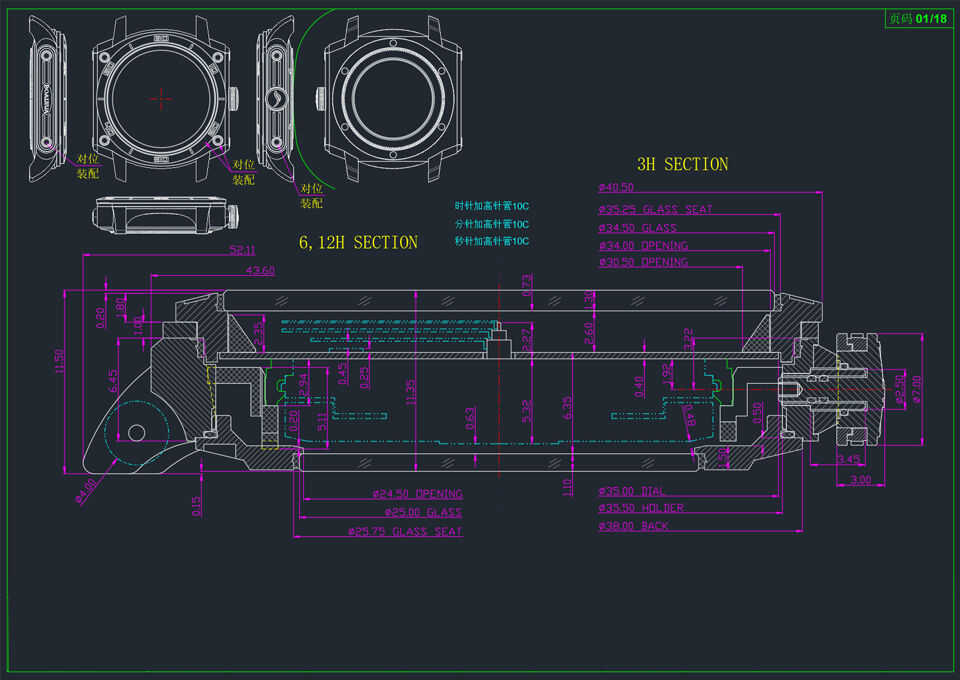

・Based on the confirmed exterior dimension drawings, proceed with internal structural design. Create detailed 3D CAD models and 2D engineering drawings

・Content includes: Part breakdown, movement mounting method, waterproof structure, case and strap connection structure, technical/process requirements, assembly requirements, etc.

・Key Confirmation Points: Material selection, technical feasibility, fit tolerances between parts, assembly processes, acceptance criteria.

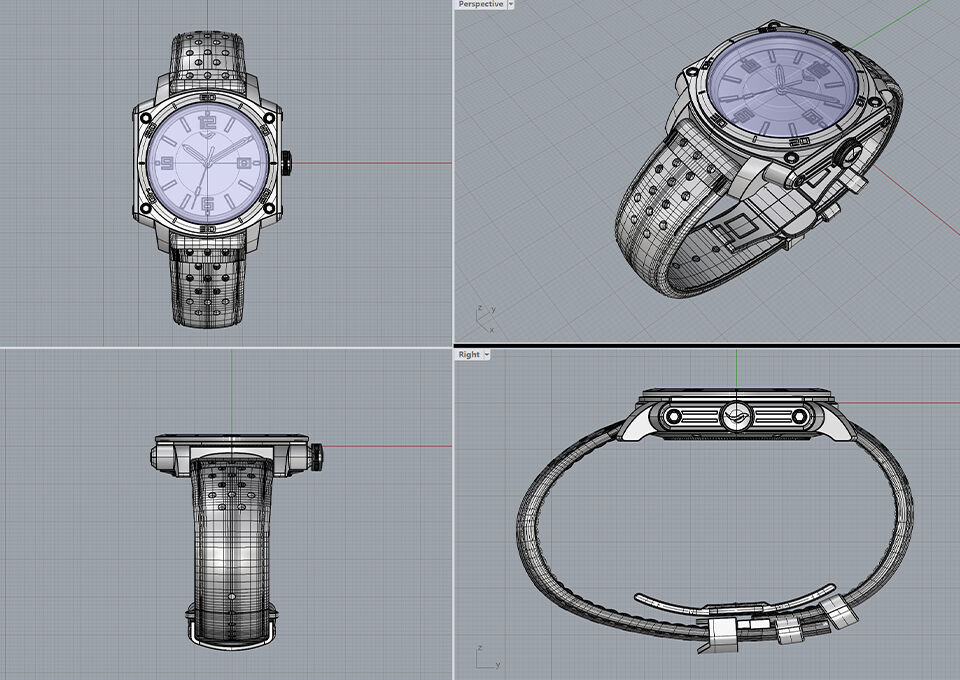

・3D renderings are produced according to client needs.

・Based on the final CAD model, they convey a realistic product design effect

Explore our standout projects, showcasing Burriva's commitment to intentional design, innovative materials, and precision manufacturing.

Choosing the right partner is crucial for bringing your watch concept to life. Our distinctive edge lies in a blend of creative design, precision engineering, and a steadfast partnership approach.

For over 20 years, we have specialized exclusively in custom watch manufacturing. This deep industry knowledge allows us to embrace challenges, streamline processes, and deliver solutions that are both innovative and reliably executed.

Our dedicated R&D team constantly pushes boundaries. We are driven by a pursuit of innovation, actively exploring new materials, advanced craftsmanship, and contemporary design trends to ensure your watch is both feasible and forward-thinking.

We believe the best results come from true collaboration. Our process is built on transparent communication and synergistic exploration. We work with you, not just for you, ensuring your vision remains at the heart of every decision.

Absolutely. We recommend beginning with as much detail as you can provide—such as brand philosophy, inspiration images, reference timepieces, or functional requirements—to ensure our designers and engineers fully grasp your vision. Even if you don't have formal drawings, a concept description combined with visual references allows us to initiate a productive dialogue and collaboratively refine your idea into a production-ready model.

We offer a wide selection of materials for watch and components, including 316L steel, 904L steel, TA2/TC4 titanium, Damascus steel, tin bronze, 925 silver, and 18K gold. A variety of plating finishes — such as IP gold (rose, yellow, gunblack) and DLC — are also available to achieve the desired aesthetics. We will advise on the optimal material and finish based on your priorities for design, durability, and cost.

The timeline varies based on complexity, from standard designs to fully custom mechanics. A typical project ranges from 4 to 8 months, covering stages from concept design and engineering to prototyping and mass production. We provide a detailed schedule after the initial consultation.

Our standard MOQ starts at 300 pieces for custom watches, but we offer flexible solutions. Please contact us to discuss options tailored to your specific needs.

Your designs and intellectual property are of paramount importance. We protect them with a confidentiality agreement(NDA), which we welcome signing before the cooperation.

Building5, No.459 Xiecao Road, Xiegang town, Dongguan, Guangdong