Choose from our range of market-proven standard buckle bases, then personalize with key options like surface finishing, laser engraving, and plating colors. Create a branded component that’s uniquely yours, with shorter lead times and optimized costs.

By starting with our standard buckle bases, you significantly reduce upfront investment and accelerate your product launch timeline.

Personalize key visible areas with your logo and choice of finish to make a standard component feel uniquely yours.

Explore our standout projects, showcasing Burriva's commitment to intentional design, innovative materials, and precision manufacturing.

Made of TA2 pure titanium, it’s hypoallergenic and light. The brushed or sandblasted finish adds a sleek look and a premium touch, so it’s as comfortable as it is good-looking.

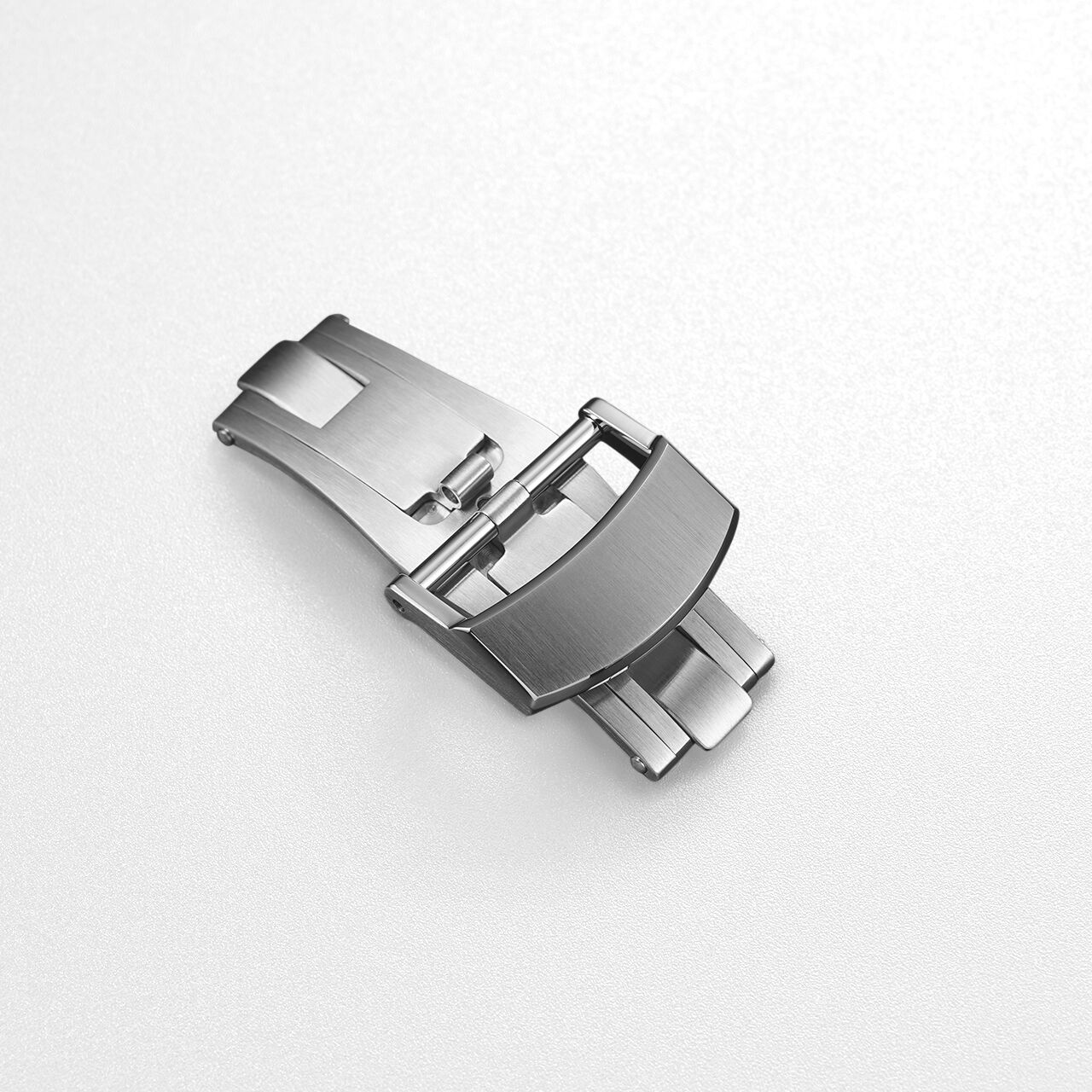

Made from 316L stainless steel, this buckle provides excellent corrosion resistance and robust durability. The material's excellent formability allows for a variety of surface finishes, from polished to brushed, making it a common and reliable choice for buckle manufacturing.

Forged in 18K gold, this buckle offers a satisfying, warm weight and enduring value. Choose from yellow, rose, or white gold, each with a deep luster, designed to be the defining accent on a luxury timepiece.

Our end-to-end buckle customization covers every detail—from materials and finishes to colors, engraving, and sizing—ensuring seamless alignment with your brand and product line.

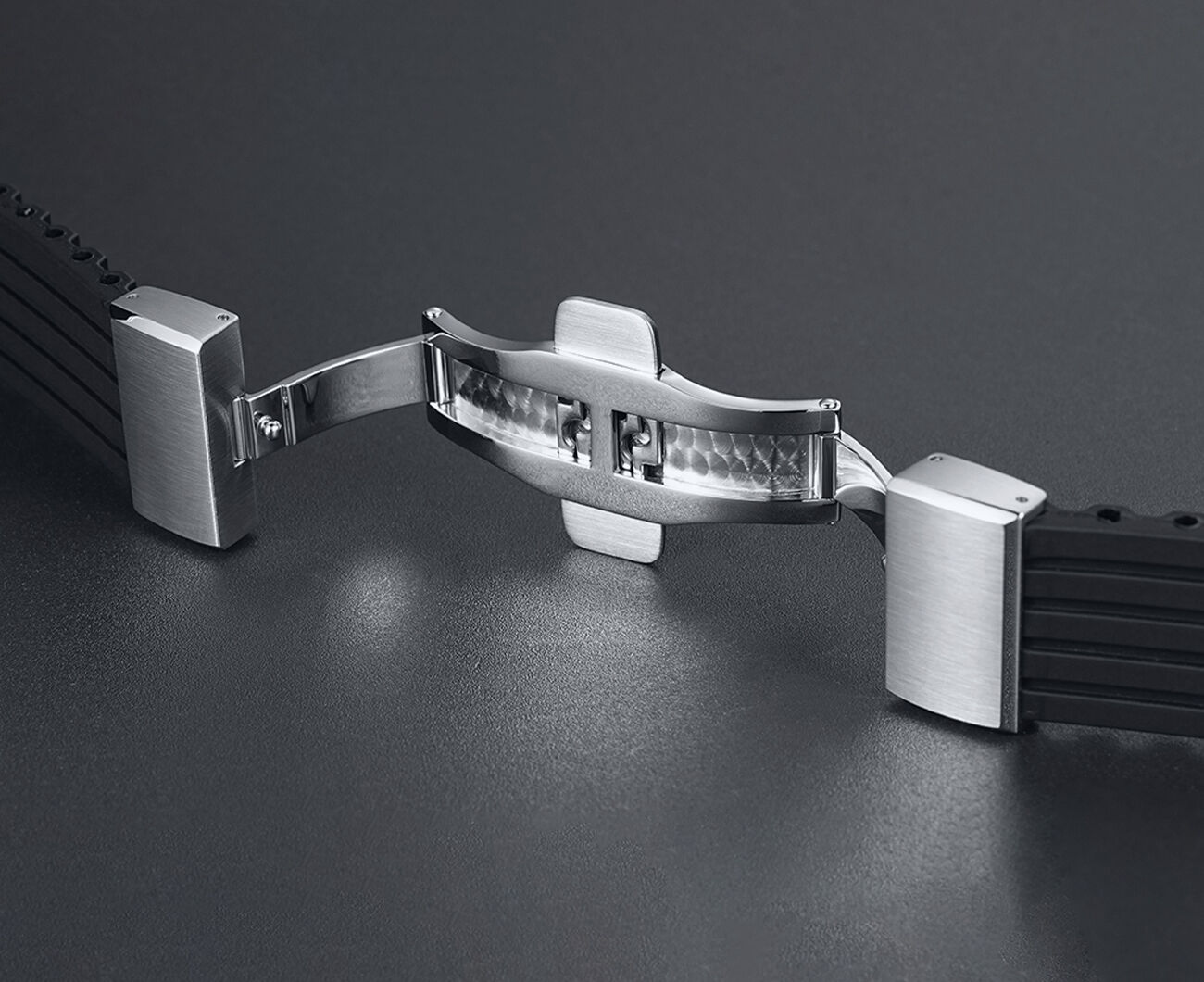

Micro-adjustable Folding Clasp

Micro-adjustable Folding Clasp

Combines security with on-the-wrist adjustability for optimal comfort.

Hidden Clasp

Hidden Clasp

Multi-function Deployant

Multi-function Deployant

Tang Buckle

Tang Buckle

Double Push-Button Butterfly Clasp

Double Push-Button Butterfly Clasp

Provides a symmetrical, secure closure with an elegant operation.

Safety Lock Clasp

Safety Lock Clasp

Start your personalization based on standard buckles. Following a clear 4-step workflow, we ensure precision in realizing your vision while guaranteeing quality and timely delivery.

Browse our product catalog and select the most suitable base style according to your strap type (width, material) and design style.

Finalize details like surface finish (e.g., polished, brushed), plating color (e.g., gold, black PVD), and brand identification (e.g., laser engraved/etching logo).

We will provide visual renderings or physical samples for your approval. Upon confirmation, we'll swing into action with efficient production.

Each batch undergoes strict quality inspection to ensure compliance. After passing the quality check, products are carefully packaged and delivered reliably as scheduled.

Explore our customization solutions covering surface finishes, color plating, brand logo engraving, and precise detail adjustments to meet personalized design and quality demands for high-end products.

1 2 3 4

1 2 3 4

Surface Treatment

・Polished

・rushed

・Sandblasted

・Combination

Color & Plating

・Silver

・Gold

・Black (PVD)

・Other PVD Colors

Branding

・Logo / Laser Engraved Logo

・Etching

Detail Adjustment

・Fit Tolerance (Clearance Fit)

・Edge Finishing

With 20 years of specialized manufacturing experience in watch components and serving renowned global brands, we possess a deep understanding of the market needs and quality essence of semi-custom watch buckles.

Relying on dedicated, scaled production lines and a mature supply chain tailored for buckle manufacturing, we ensure stable, on-time delivery from your first sample to your large order.

We have established an ISO 9001-compliant quality management system that covers the entire production process, supported by professional testing equipment to ensure every single buckle meets high standards and consistency requirements.

From technical drawing to finished part, we provide feasibility analysis and technical advice, ensuring all manufacturing complexities are resolved under one roof.

We primarily support laser engraving, printing and chemical etching. The recommended process depends on logo complexity and material.

We work with TA2 titanium, TC4 titanium, Damascus steel, 904L steel, 316L steel, tin bronze, 925 silver, and 18K gold to produce various watch components.

We offer micro-adjustment clasp, Tang buckle, titanium buckle, diving watch clasp, butterfly clasp, multi-function deployant buckle and hidden clasp.

The MOQ ranges from 300 to 1000 units.

Prototype samples typically take 50–60 days, while bulk orders require 90–120 days for completion. The specific time will depend on the actual situation.

Building5, No.459 Xiecao Road, Xiegang town, Dongguan, Guangdong